MIL-DTL-6193D

inspection set forth in this specification shall become a part of the contractor's overall inspection system

or quality program. The absence of any inspection requirements in the specification shall not relieve the

contractor of the responsibility of ensuring that all products or supplies submitted to the Government for

acceptance comply with all requirements of the contract. Sampling inspection, as part of manufacturing

operations, is an acceptable practice to ascertain conformance to requirements, however, this does not

authorize submission of known defective material, either indicated or actual, nor does it commit the

Government to accept defective material.

4.3 Qualification inspection. Qualification inspection shall consist of the examinations and tests

specified in table IV. Samples subjected to group I testing shall be divided and subjected to group II and

group II tests. Qualification Inspections and tests shall be performed at a laboratory acceptable to the

Government (see 6.3) on sample units produced with equipment and procedures normally used in

production. Use of alternate materials, plating, and processes shall be identified in the product test

documentation (see 3.3).

4.3.1 Qualification test articles. Samples for qualification shall be representative of the products

proposed to be furnished to the Government. Qualification test articles shall consist of 10 universal joints

for each type and size of universal joint for which qualification is desired.

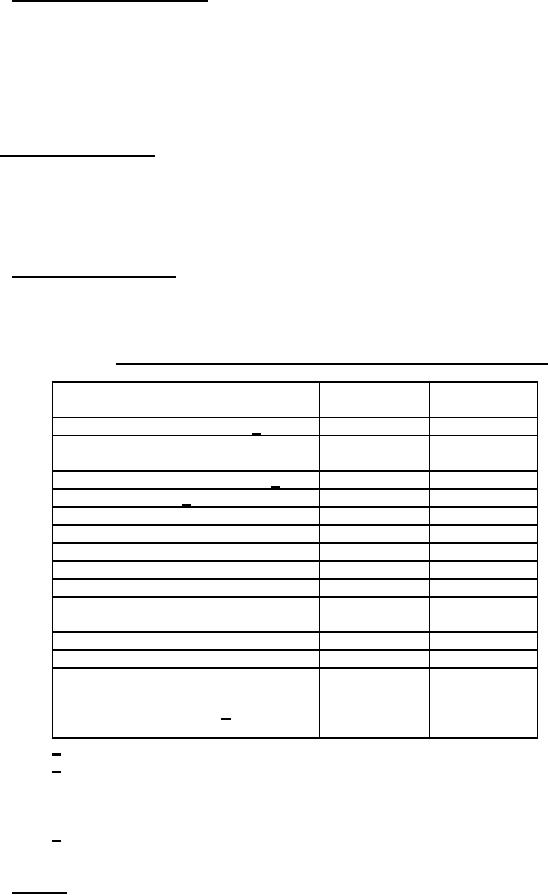

TABLE IV. Qualification inspection and verification of qualification inspection.

Requirement

Test method

Inspection

paragraph

paragraph

Group I (10 samples) 1/

Visual and mechanical inspection

Verification of plating thickness 2/

---

Ozone resistance 2/

Hardness

---

Group II (4 samples)

Torsional play

End and side play

Tightness

Axial load

Tightness

Static torque load

Group III (4 samples)

Endurance (sequence shown below)

Endurance

Lubrication retention 3/

Torsional play

1/ Any samples not tested shall be retained as a reference standard.

2/ At the discretion of the qualifying activity the manufacturer may verify

compliance stating testing has been completed in accordance with

ASTM B659 or 4.7.9 as applicable.

3/ Three samples from endurance test with lubrication retention covers

in place.

4.3.2 Failures. One or more failures shall be cause for refusal to grant qualification approval.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business